Industrial fan systems are generally large-scale ventilation systems actively used in industrial environments. The prices of industrial fans vary depending on the type of fan selected. These components are commonly used in industrial factories, facilities, warehouses, workshops, and similar locations, helping to reduce operating costs. Such ventilators are specifically designed for various purposes, such as cleaning the air, absorbing dust and smoke, eliminating odors, circulating air, or controlling humidity.

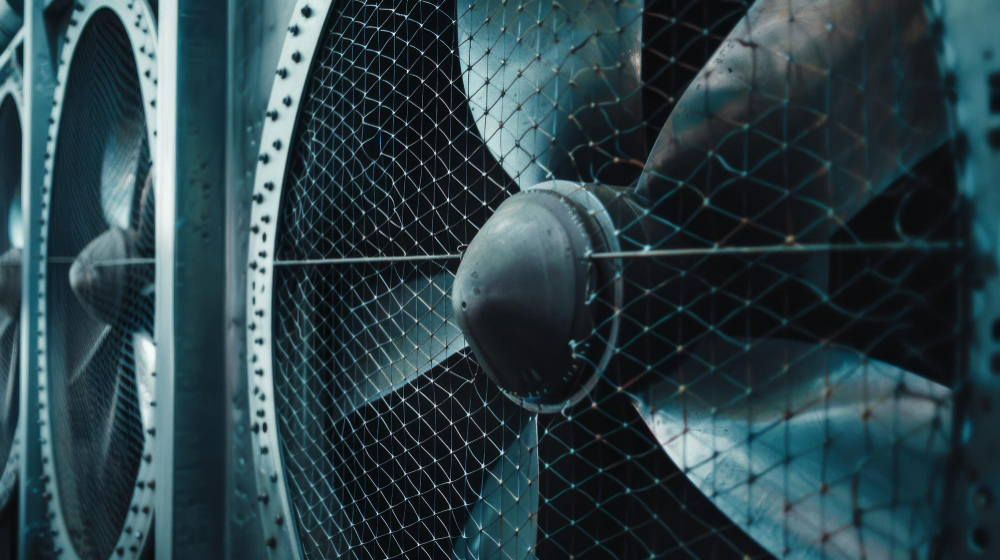

Industrial ventilators are designed for use in challenging working environments and are therefore manufactured with highly durable materials and high power. Their ability to move large volumes of air effectively makes them ideal for ventilating large spaces. These types of ventilators come in different models. For example, they can be categorized as cased, jet-type, cellular, or axial ventilators. Additionally, some models are equipped with special filter systems designed to remove specific pollutants or particles from the air.

These devices, which help improve air quality to protect the health of employees in industrial environments, offer highly efficient usage when maintained under proper conditions and regularly inspected. Additionally, industrial fans are developed in various types to cater to different applications and needs.

Industrial fans are highly functional products used for various purposes such as ventilation, heating, cooling, drying, and dust collection. The working principle, capacity, structure, and application areas of industrial fans result in different types. These fans are generally divided into two main groups: axial fans and radial fans.

Axial Fans: Axial fans are a type of fan that provides airflow parallel to the axis on which the blades actively rotate. They are commonly used in low-pressure and high-volume ventilation systems. The main advantages of axial fans include low energy consumption, easy maintenance and installation, and quiet operation. However, their disadvantages include providing low pressure, being noisy at high speeds, and experiencing efficiency loss in dusty environments. Axial fans have four subcategories: bladed axial fans, tunnel-type axial fans, wall-mounted axial fans, and roof-mounted axial fans.

Radial Fans: Radial fans, on the other hand, provide airflow perpendicular to the axis on which the blades rotate. They are frequently used in medium-flow and high-pressure ventilation systems. The advantages of radial fans include generating very high pressure and working efficiently in dusty environments. However, their disadvantages include difficult installation and maintenance, high energy consumption, and noisy operation. Radial fans are categorized into three subgroups: centrifugal fans, jet fans, and turbo ventilators.

Industrial fans are devices known for altering the direction of airflow with high pressure to remove smoke and polluted air in various businesses. These fans have the capability to operate with air volumes ranging from 1,000-200,000 m³/h to 23,000-160,000 m³/h and pressure levels up to 1,200-2,000 mmss. Industrial fans can be categorized into different types depending on their application area. These include:

Among these types, axial fans are the most commonly used. The primary purpose of axial fans is to quickly facilitate air transfer. Additionally, they can be used as free discharge, circular cross-section, or with air duct connections. These fans are very easy to install and use.

Selecting a model that matches the requirements of your ventilation system is crucial when choosing an industrial fan. Key factors to consider during the selection process include:

Industrial fans are functional devices designed to move large volumes of air. They are essential for meeting ventilation needs in various settings. The applications of industrial fans can be categorized as follows:

Industrial fans are primarily used as ventilation devices. When asked about their purpose, various functions depending on their application can be highlighted. Fans remove cold, hot, or polluted air by directing it outward, replacing it with fresh air to refresh the environment. Specifically, industrial fans facilitate the rapid removal of flammable, explosive, or toxic gases, making the environment safer and healthier.

Industrial fans operate using electrical energy and are essential for air purification. Exploring the category of industrial fans can make selecting the right product for your needs much easier.

Industrial fan prices are among the most frequently asked topics. Fans used in industrial settings vary based on brand, type, diameter, speed, and price options. Each fan type and model comes with significantly different pricing. Naturally, fans with diverse features designed for industrial use are not expected to have the same price. Users looking to select a fan with specific features can easily find suitable options using filters such as fan type, voltage, diameter, and speed in the category section.

ERF Group stands out as a qualified company offering affordable prices for the industrial fan systems you need. With a long history of delivering high-quality fan production, our company's priority has always been to provide products that meet your requirements. Thanks to this principle, ERF Group continues to grow and improve daily. You can purchase the industrial fan systems you need with just one click through our website.

All the fan models available for sale in our company are specially designed as movable fans with varying features. Each of these products operates by moving air. Once powered, the blades start rotating at a speed adjusted to the motor's capacity. The placement of the fans depends on the area where air transfer is required. They are primarily used to remove polluted air in enclosed spaces. While industrial fans vary based on their application areas, their functionalities also differ significantly. These products are indispensable for large-scale industrial environments.

Another critical factor to consider when purchasing industrial fans, known for their functional features, is selecting the right company. Without the correct choice, achieving the expected performance from the purchased fan system may not be possible. Our company delivers highly satisfying productions and offers a wide range of products for trouble-free fan use over the years. To purchase the fan you need, simply visit our website and complete the purchase with one click. When it comes to quality and reliability in fans, ERF Group continues to stand out as the best choice.