Kitchen exhaust fans are devices specifically designed to expel steam, smoke, and odors generated during cooking. As a key component of range hood systems commonly used in homes, kitchen fan models are also found in industrial kitchens where large-scale cooking takes place.

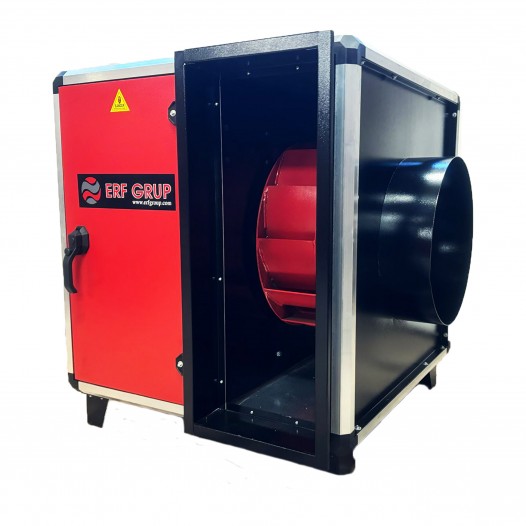

Restaurant kitchen exhaust fans are known for their durable construction, capable of withstanding high temperatures and grease particles. Professional kitchen fan models, which operate in conjunction with hood systems, quickly remove contaminated air produced during the cooking process. Typically designed as radial or roof-type models, quiet kitchen exhaust fans are manufactured from highly heat-resistant materials to ensure safety and reduce the risk of fire.

A kitchen exhaust fan is the main component of the hood positioned above an oven or stove. The primary purpose of these kitchen fan models is to quickly remove odors, steam, smoke, grease, and other particles produced during cooking from the air. These kitchen extractor systems generally contain a fan powered by an electric motor. The fan draws air from inside the hood and passes it through a filtration system. The filters capture smoke, grease, and other airborne particles. After filtration, the cleaned air is either expelled outside or recirculated back into the kitchen.

A kitchen exhaust fan stands out as a key component used above ovens. The main purposes of these devices can be summarized as follows:

Improves air quality: Prevents grease, smoke, and odors from lingering in the air, helping to maintain a cleaner and healthier kitchen environment.Eliminates unpleasant odors: Removes cooking smells, preventing them from spreading to other rooms in the house.Reduces grease buildup: Filters airborne grease particles, minimizing residue on furniture and kitchen surfaces.Controls humidity: Absorbs steam generated during cooking, helping to maintain a balanced humidity level.

Industrial kitchen exhaust fans, on the other hand, are designed to handle high air volumes efficiently and to withstand demanding conditions. The production process of these units typically includes the following stages:

Design phase: The kitchen fan is designed based on customer needs and the technical specifications of the kitchen. Factors such as noise level, durability, and energy efficiency are generally taken into account.Material selection: Durable and corrosion-resistant materials such as galvanized steel, stainless steel, or aluminum are commonly used.Fan blade production: Fan blades are manufactured from sheet metal through cutting or molding processes. Their shape and angle are optimized to improve airflow efficiency.Motor selection and assembly: High-performance industrial electric motors are used. The motor is connected to the fan blades to ensure smooth rotation.Body manufacturing: The fan housing is produced by cutting or welding sheet metal materials. The body protects internal components and provides mounting points for assembly.Filtration system: Grease traps, carbon filters, or other specialized filters are integrated to maximize suction power and ensure cleaner air output.Testing and quality control: The manufactured fans are tested for parameters such as pressure, airflow, noise level, energy consumption, and vibration. The quality control process ensures that each fan meets the required standards and delivers reliable performance.

A kitchen exhaust fan is an essential component not only for home kitchens but also for large-scale food production facilities, cafes, and restaurants. During food preparation and cooking, contaminated air and airborne particles can cause serious harm to environmental health. For this reason, according to regulations set by the Ministry of Environment, the installation of kitchen exhaust systems is mandatory in such production areas. Therefore, the use of kitchen exhaust fans within these systems is compulsory. These fans ensure that food production takes place under suitable conditions and prevent uncontrolled air circulation. At the same time, they offer significant energy-saving advantages during operation.

Kitchen exhaust fans are widely used in large food preparation and consumption areas such as shopping mall food courts, hotel kitchens, exhibition halls, restaurants, convention centers, and airport kitchens. The distinctive features of kitchen exhaust fans include their backward-curved, wide-blade plug fan design, which allows for easy cleaning. This naturally contributes to more hygienic use.

To protect kitchen exhaust systems from hazards such as fire, the fan motor is mounted on the exhaust side in a way that keeps it outside the main airflow. This design helps prevent fire risks and ensures a longer service life. Both the exhaust fan and the fresh air fan in the system can operate simultaneously. The units are manufactured in dimensions that allow them to fit within the ventilation system. Additionally, the electrical automation system enables synchronized control of both the exhaust and fresh air fans.

Before oily air produced during cooking is released into the atmosphere, it is filtered to reduce its environmental impact, ensuring that only clean, harmless air is discharged.

Key features of kitchen exhaust fans can be summarized as follows:

Choosing the right type of exhaust fan is crucial for ensuring efficient air circulation and proper ventilation in kitchens. These fans not only help move air within the space but also play an active role in introducing fresh air, removing stale air, and improving overall air quality. Accordingly, kitchen exhaust extractor prices may vary. One of the most important factors to consider when determining pricing in this field is selecting the right manufacturer.

ERF Group is a qualified company that specializes in producing high-quality, low-noise kitchen exhaust fans. Having long been a step ahead of its competitors in fan manufacturing, our company prioritizes providing fan systems that meet your specific needs. Industrial kitchen exhaust fans produced with a focus on quality, reliability, and durability offer numerous long-term advantages.

Therefore, benefiting from the convenience of ERF Group's silent kitchen exhaust fans is extremely easy. If you want to experience the quality of ERF Group in kitchen fan models, you can visit our website and contact our team of experts. ERF Group always keeps its kitchen fan prices within competitive and affordable ranges.