Industrial fan types are actively used today in industrial and commercial applications. These ventilation products are preferred for purposes such as air purification and cooling. In addition, energy-efficient industrial fans are designed to deliver high airflow performance. In this context, warehouse ventilation solutions-which have become particularly important-optimize fresh air intake and exhaust in the areas where they are installed. As a result, efficient, energy-saving, and safe operation becomes possible.

Humidity and odor control fans designed for storage areas are effective and practical devices used to ensure clean air circulation indoors, enable fresh air flow, and regulate temperature more precisely. These fans generally stand out with their compact design features. Today, industrial ventilation fans are not intended for residential use but are widely utilized in facilities such as production plants, warehouses, workplaces, and shopping centers. By enabling internal air circulation within warehouses, these systems play a crucial role in maintaining comfort and health. Highly efficient air exchange is achieved through the combined use of fans, vents, filters, ducts, and directional louvers.

Industrial exhaust systems for warehouses not only purify indoor air but also successfully remove odors, humidity, and harmful gases from the environment. Therefore, when selecting ventilation systems suitable for specific environments, technical factors such as energy consumption, capacity, quiet operation, and material durability should always be considered. ERF Group delivers project-specific solutions in warehouse ventilation with long-lasting, cost-effective products certified with ISO and CE standards. With expert support and high-quality equipment, these ventilation systems create a healthy and comfortable environment, especially in storage facilities.

Warehouse ventilation systems are functional solutions that help achieve proper air quality as well as the required temperature and humidity levels in actively used storage facilities. When insufficient air exchange occurs in such environments, unwanted condensation may form on stored products. This condensation can damage product packaging or the products themselves, leading to sales and quality issues. Warehouse ventilation solutions designed for storage areas allow users to easily regulate incoming air levels through adjustable settings tailored to specific needs. In addition, by supplying both warm and cool air in combination with climate control units, the formation of excess humidity is prevented.

Especially in areas constructed for storing products, such as warehouses, greater care should be taken when selecting ventilation systems. Factors such as the type of shelving used, the nature of the stored goods, and the overall usage pattern of the warehouse play a decisive role in determining the appropriate ventilation method. For example, ventilation requirements differ significantly between facilities used for food storage and those used for storing household appliances. With its wide range of fan systems, ERF Group supports users in ensuring clean and healthy air circulation in both small- and large-scale storage areas.

Developments taking place today lead to the continuous addition of new features to ventilation systems. In this context, it can be said that fire safety-compliant fan products provide significant advantages for businesses. Each product requires different temperature conditions during its storage period. Moreover, prolonged exposure of warehouse employees to such environments can cause serious health and safety issues. To eliminate these risks, warehouse ventilation fans specially designed for storage areas serve as highly functional systems that help ensure employee safety.

Some machinery actively used inside warehouses operates on gasoline, diesel, or LPG. Especially for vehicles used in transporting or relocating goods, ventilation systems are essential. The polluted air emitted by such machinery can cause serious harm to both stored products and warehouse personnel. To prevent these potential hazards, warehouse ventilation and air circulation systems should be integrated into storage facilities. Accordingly, the types of ventilation fans used in warehouses can be listed as follows:

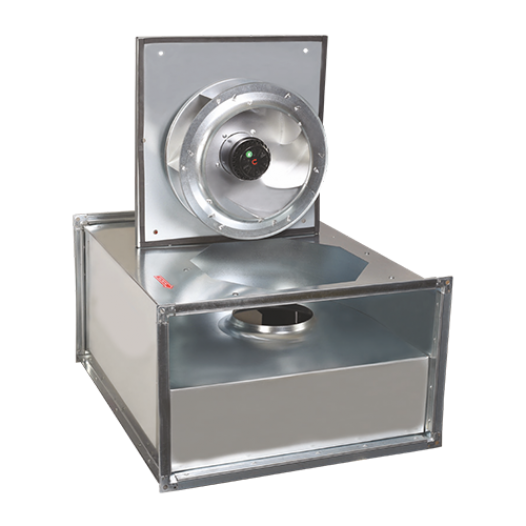

Duct-type fans: These fans can be installed smoothly between two ducts. In this system, air flows linearly through the fan. They are available in axial, radial, and mixed-flow variants.

Axial fans: This type of fan creates a pressure difference through the axial movement of air within the environment. As a result, they are commonly used in ventilation systems that require high airflow and low pressure. Depending on the application, axial fans can be produced with different housing types.

Industrial ventilation systems are widely used equipment with a broad range of applications whenever ventilation needs arise. They are especially utilized to ensure proper airflow in workshops, parking garages, industrial facilities, food production areas, and similar structures. However, choosing the right fan cannot be based solely on physical dimensions or price range. The technical criteria that should be considered when selecting a fan can be listed as follows:

Airflow rate and pressure requirements: The first factor to consider when selecting a fan system is determining the required airflow rate and static pressure of the system. Airflow rate indicates the volume of air a fan can move within a specific period, typically per hour. Static pressure, on the other hand, refers to the force needed to overcome resistance within the system.

Duct cross-section and compatibility: The cross-section and dimensions of the duct to which the fan will be connected directly affect fan selection. The fan's inlet and outlet diameters must be compatible with the duct size. Otherwise, performance losses, air leakage, or turbulent airflow issues are likely to occur.

Energy efficiency and motor power: The motor power of a fan is critical not only for meeting airflow requirements but also for long-term energy consumption. An excessively powerful motor can lead to energy waste, while an underpowered motor may cause performance problems.

Noise level: In industrial environments, noise levels can be a critical factor. Especially in production areas where personnel work actively, high-noise ventilation systems can reduce comfort and productivity. Therefore, the noise level should always be evaluated during fan selection.

Ease of installation and maintenance: Modern fans are typically installed in wall penetrations, ceiling voids, or confined spaces. Compact fan designs offer significant advantages in terms of installation flexibility. Additionally, fans that are easy to disassemble and reassemble simplify maintenance. Issues such as filter clogging, dust accumulation, or grease buildup require regular cleaning, making accessible panels and easy motor access essential.

Application area and material quality: Fan selection should take into account the physical conditions of the intended environment, such as humidity, dust, and temperature. Choosing inappropriate materials can shorten the fan's lifespan and cause irreversible damage to the entire system.

One of the most important factors to consider when choosing among warehouse ventilation solutions is selecting the right company. ERF Group, which consistently delivers work at the highest quality standards in the production of industrial ventilation systems, continues to serve as a leading company in the sector. On our website, which features a wide range of products, energy-efficient industrial fans suitable for every need are offered at competitive price ranges.