One of the most critical areas that must be carefully designed during the factory setup process is the ventilation system. Factory ventilation should be planned with a strong focus on employee health and safety, as harmful substances such as dust and gases tend to accumulate during production processes.

When a ventilation system functions properly, these harmful substances are effectively removed from the environment. While installing the system, it's essential to consider the production capacity of the factory. The system should also ensure adequate airflow, thereby improving the indoor air quality in the working environment.

Businesses are always in search of solutions that offer energy savings in their production areas. Therefore, implementing the right ventilation system can also help reduce operational costs.

In addition, legal regulations in the Republic of Turkey require certain workplace safety and environmental standards to be met. As a result, beyond improving operational efficiency, your ventilation system must also comply with regulatory obligations.

Ventilation System Capacity: Your ventilation system must have a capacity that matches the size of your facility and the level of air pollution generated by production processes. Insufficient capacity not only reduces air quality but also poses a risk to employee health. Accurate calculations are the first step in building an effective and efficient system.

Ductwork Design: Proper duct design is essential to ensure consistent airflow. Poorly designed ducts can obstruct the circulation of clean air and fail to remove pollutants adequately. For optimal airflow, a professionally planned and organized duct system is critical.

Energy Efficiency: Ventilation systems can be designed to minimize energy consumption, making them both eco-friendly and cost-effective. Technologies such as energy-efficient motors, speed-controlled fans, and heat recovery systems can significantly reduce energy costs.

Regular Maintenance and Cleaning: Routine cleaning and maintenance of ventilation equipment help preserve system efficiency and extend its lifespan. The accumulation of dust and debris can negatively impact airflow and reduce overall performance. For this reason, a preventive maintenance schedule should be implemented.

Air Quality Control: A ventilation system should not only circulate air but also filter out harmful particles and chemical vapors. Using advanced filtration systems ensures a clean and healthy work environment.

Compliance with Legal Standards: Ventilation systems must be designed and operated in accordance with local and national regulations. This not only helps protect employee health but also ensures that the facility meets its legal obligations.

Emergency Response Integration: In the event of fire, gas leaks, or other emergencies, ventilation systems should be integrated with evacuation systems. These systems enhance worker safety and minimize potential risks.

Climate Control Capabilities: Ventilation systems should go beyond air exchange by helping to regulate temperature and humidity. In industries where specific temperature or humidity ranges are critical, systems with climate control features are essential.

Modular and Flexible Design: Having a ventilation system that can be modified based on the factory's size and changing needs offers significant advantages. A modular design allows for easy adaptation when new sections are added, helping to optimize investment costs.

Filtration Systems: Ventilation equipment should include advanced filtration systems capable of effectively removing harmful particles and dust from the air. High-quality filters enhance air quality, protect employee health, and eliminate contaminants that could negatively impact production.

Effective factory ventilation methods aim to ensure clean airflow within industrial facilities, helping to protect employee health while optimizing production processes.

Here are some common ventilation methods used in factories:

Mechanical Ventilation Systems: Mechanical systems consisting of fans, aspirators, and ductwork provide balanced airflow throughout all areas of a factory. These systems are particularly effective in high-production zones, as they efficiently expel polluted air and accelerate the circulation of fresh air.

Natural Ventilation Methods: Natural ventilation through windows, doors, and air vents helps reduce energy consumption. However, these methods are usually supported by mechanical systems to improve overall efficiency and effectiveness.

HEPA and Carbon Filtration Systems: In areas with high levels of pollutants, HEPA and carbon filters are used to eliminate harmful particles, chemicals, and odors from the air. This method protects worker health and enhances product quality.

Local Exhaust Systems: Used in specific areas such as welding, painting, or chemical processes, these systems capture pollutants at the source, preventing them from spreading to other parts of the facility.

Heat Recovery Systems: Designed to improve energy efficiency, these systems recover heat from the exhaust air during ventilation. This method offers significant economic and environmental benefits.

Humidity and Climate Control Systems: These systems regulate temperature and humidity levels within the factory, enabling more stable production processes. They also help prevent product spoilage and increase employee comfort.

Using one or a combination of these methods depends on the specific needs and structure of the factory. With the right selection and regular maintenance, you can establish an efficient ventilation system that boosts your factory's productivity and sustainability.

Ensuring healthy airflow in factories is critical for both employee safety and the efficiency of production processes. You can achieve this by implementing the following practices:

Installation of the Right Ventilation System: A ventilation system with the appropriate capacity should be installed based on the size of the factory, production processes, and sources of air pollution. Devices such as mechanical aspirators, centrifugal (snail) fans, and cell-type aspirators effectively remove polluted air while circulating clean air throughout the facility.

Use of Filtration Systems: Advanced filtration systems should be used to eliminate harmful gases, dust, and airborne particles. Especially in industrial settings, HEPA and carbon filters improve air quality and create a safe and hygienic working environment.

Balanced Airflow: Maintaining a balance between air intake and exhaust points ensures consistent airflow across all areas. Properly designed ductwork and exhaust systems help achieve uniform air circulation throughout the facility.

Climate and Humidity Control: Temperature and humidity levels in factories affect both employee comfort and product quality. Climate control systems regulate environmental conditions and help keep them within ideal ranges.

Regular Maintenance and Cleaning:To maintain system performance, ventilation equipment must be cleaned and maintained regularly. Dust, dirt, and grease buildup can reduce efficiency. Therefore, scheduled inspections and maintenance must not be neglected.

Emergency and Safety Systems: Ventilation systems should be integrated with emergency response mechanisms for situations such as fires or gas leaks. These systems help rapidly evacuate dangerous gases, enhancing employee safety and reducing risk. By implementing these methods, you can create healthier airflow in your factory, leading to higher productivity and improved workplace safety.

When a factory lacks a ventilation system, uncontrolled air pollution in the indoor environment poses serious health and safety risks. Dust, chemical vapors, gases, and unpleasant odors produced during manufacturing processes accumulate and can lead to respiratory issues among workers. Insufficient airflow reduces oxygen levels in the workplace, negatively impacting employee performance and productivity.

The absence of a ventilation system can also cause machines and equipment to overheat, leading to excessive indoor temperatures. This not only lowers product quality but may also disrupt production processes. In emergency situations such as fires or gas leaks, the inability to exhaust dangerous gases increases safety hazards significantly.

The lack of proper ventilation is not just a threat to employee health and workplace safety, but also a major compliance issue with legal regulations. For these reasons, an effective ventilation system is an indispensable component of any factory environment.

Industrial Ventilation Systems: Industrial ventilation systems are developed to improve air quality in production facilities, protect worker health, and optimize manufacturing processes. These systems combine mechanical ventilation devices, natural airflow inlets, and filtration technologies to deliver complete solutions. They are especially ideal for industries where chemical vapors, harmful gases, and particles must be effectively removed from the air. With energy-saving features and modular designs, these systems provide both environmentally friendly and cost-effective solutions for businesses.

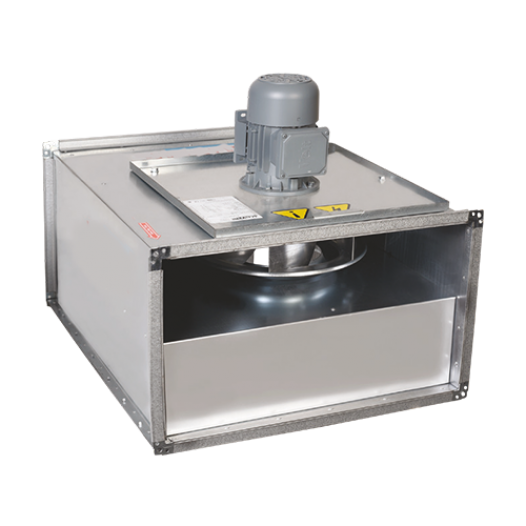

Use of Cell-Type Aspirators: Cell-type aspirators are a fundamental part of industrial ventilation systems. They ensure high-performance air exchange in large spaces. With extruded aluminum and epoxy-coated galvanized profiles, these units offer durable construction and quiet operation, providing comfort in industrial settings. Thanks to their energy-efficient motors and filter-equipped options, they offer eco-friendly ventilation. Their airtight design and long operational life help minimize maintenance costs, while maintaining superior air quality in environments like factories and warehouses.

Centrifugal (Snail) Fan Systems: Centrifugal (snail) fan systems provide efficient airflow management across wide areas with their spiral design. These fans are known for their high airflow capacity and quiet performance, making them a preferred choice in industrial plants. Made from durable materials, they are suited for harsh working conditions and help reduce operating costs through energy efficiency.

From factories and food production facilities to chemical processing plants and logistics warehouses, snail fan systems deliver efficient ventilation solutions in a variety of industrial environments.