The ventilation need in highway tunnels arises due to air pollution caused by the heat and exhaust emissions from vehicles, making functional ventilation products essential. This air pollution, resulting from the combination of heat and exhaust fumes, negatively impacts the general health of passengers traveling in vehicles. One of the most critical measures taken during tunnel construction is the Tunnel Ventilation Systems.

The process of ventilating tunnels on highways was developed in the 20th century due to exhaust gases posing risks to human and environmental health. At this point, pollution levels can be controlled to more effectively limit the number of vehicles using the tunnel and to improve vehicle engines. This detail is extremely important for ensuring overall safety.

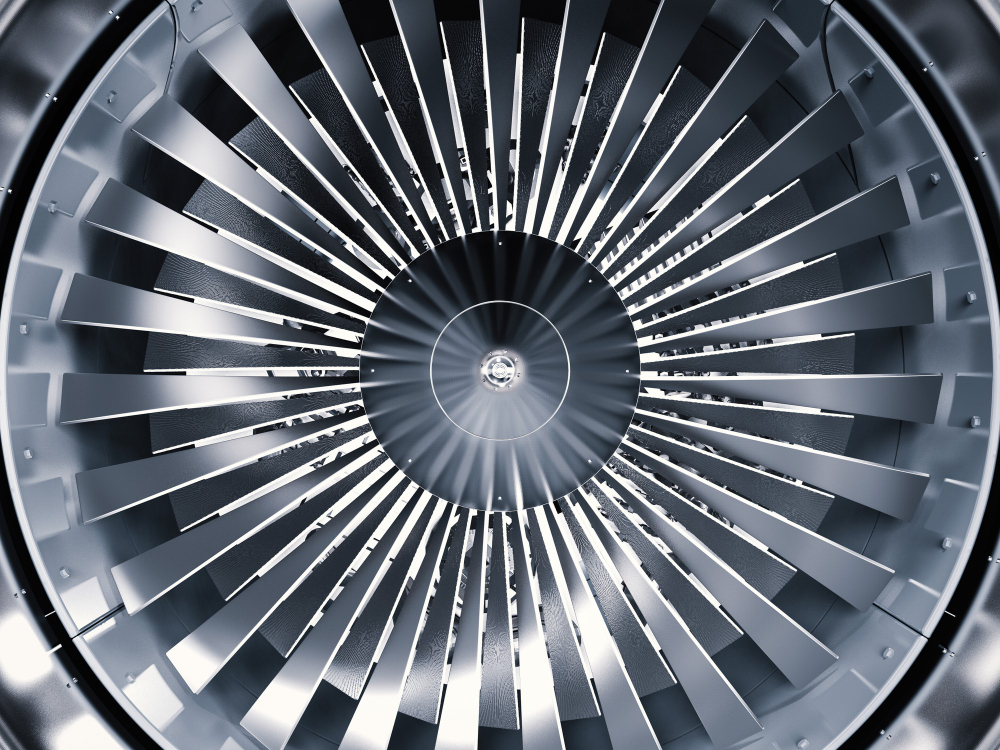

Depending on the design of tunnel ventilation systems, axial fans are generally used to expel polluted air and smoke in the event of a tunnel fire while simultaneously supplying fresh air into the tunnel. Tunnel ventilation fans are installed to circulate the air within the tunnel, removing exhaust gases, polluted air, and smoke generated during a potential fire. This creates a much safer environment for users.

Tunnel ventilation fans are primarily based on three different methods: transverse, longitudinal, and semi-transverse ventilation. In longitudinal ventilation, fresh air is supplied directly through the tunnel entrance portal, while polluted air is transported horizontally within the tunnel and expelled through the exit portal. The method by which the tunnel ventilation fan will be used depends on the length and geometric features of the tunnel being constructed. In our country, the most commonly used and effective method is longitudinal ventilation. Once the ventilation system for the tunnel is decided, all necessary calculations for ventilation are carried out.

In these calculations, key parameters such as the region where the tunnel is located, the vehicles passing through the tunnel, its geometric characteristics, and the fire load determined based on these factors are taken into account. Considering this data, detailed calculations are performed for parameters such as pressure losses within the tunnel, critical velocity, and stack effect.

At this point, critical velocity refers to the minimum speed required for smoke to flow over the fire point without reversing its direction. The components of the ventilation system to be installed must possess the thrust power necessary to achieve this speed. This ensures that smoke can be effectively evacuated from the tunnel in the event of a fire.

Traffic conditions in highway tunnels require constant monitoring of oxygen supply, pollutant concentrations, and visibility within the tunnel. Ventilation systems are critical for maintaining air quality during normal operations and for working in close coordination with traffic control systems. Ensuring the operation of ventilation systems during a fire is essential to facilitate rescue efforts.

In the event of a fire, it is crucial to keep heat and smoke as far away as possible from rescue personnel and passengers remaining in the tunnel to ensure smooth execution of rescue activities. To control the smoke and heat within the tunnel, an appropriate ventilation control system must be employed. Ventilation operates on a principle of evacuation or extraction modes, depending on specific fire scenarios. In the case of a fire, the way the ventilation is controlled largely depends on whether the source of the fire within the tunnel has been identified. Excessive pressure is generated to prevent smoke from entering the evacuation channel.

Tunnel ventilation is a functional system actively used in underground tunnels or mines. The primary purpose of these systems is to replace the air in the mine or tunnel gallery with fresh air, ensuring that workers and other equipment in the tunnel operate in a healthy environment.

Accordingly, tunnel ventilation systems are vital for protecting the health of personnel working in tunnels or mines and for maintaining workplace safety standards. A properly designed and operated ventilation system enhances air quality in the tunnel, controls factors like humidity and temperature, and optimizes working conditions. This naturally increases workplace safety and helps prevent potential accidents.

The features of tunnel ventilation fans can be listed as follows:

Air Inlets and Outlets:A series of air channels are provided to supply fresh air to the mine gallery or tunnels. These inlets typically consist of structures and channels that draw clean air from outside and distribute it within the tunnel. On the other hand, air outlets are essential for expelling used air and smoke.

Air and Fan Distribution Systems:Fans within tunnel ventilation systems are used to control airflow and ensure uninterrupted fresh air supply. These fans are usually placed at the tunnel entrances and exits and have the ability to direct airflow. Air distribution systems evenly distribute the airflow from these fans throughout the tunnel, providing more uniform ventilation.

Filtration and Air Purification:Tunnel ventilation systems often include advanced filtration and air purification components. These systems filter pollutants like gases, smoke, and dust, protecting the health of workers and improving air quality within the tunnel.

Emergency Ventilation:Specially designed emergency ventilation systems are used to safely evacuate people during incidents such as fires. These systems are specifically designed to expel smoke and ensure the flow of fresh air in emergency situations, enhancing safety during critical events.

The need for ventilation arises to supply fresh air necessary for minimizing air pollution caused by the machines used during tunnel construction. ERF Group stands out as a distinguished company that implements the most suitable ventilation solutions during the construction phase of tunnels, staying one step ahead of its competitors. Ventilation fans ensure clean air flow in the construction site environment, optimizing performance during tunnel construction. Additionally, our ventilation systems protect escape routes from smoke and heat in adverse situations such as fires.

Tunnel ventilation fan prices vary depending on the technical specifications, model of the chosen fan system, and the selected company. For this reason, being meticulous in selecting a company is essential for reaping long-term benefits. ERF Group is a highly professional company that always focuses on expectation-driven solutions when it comes to ventilation systems. With a long history of service in this sector, our company continues to grow and develop, prioritizing the fulfillment of customer needs and expectations.

On the ERF Group website, you will find a wide range of fan models offered with attractive pricing options. To make the right choice for your business and replace polluted air with fresh air using high-quality ventilation fans, you can visit our website and get in touch with our team of experts today.