Today, workplace smoke extraction can often be a neglected area, even in large production facilities with lots of ventilation. With regard to smoke extraction systems, it is extremely important that you fully understand the benefits of smoke extraction, the types of smoke equipment and the potential risks of toxic particles in the working environment.

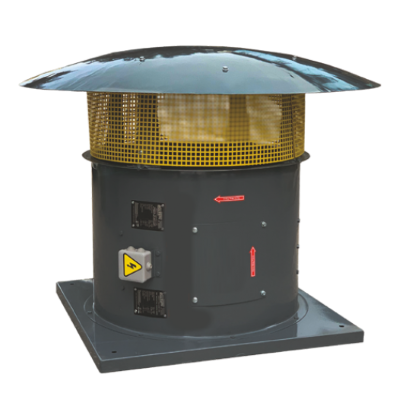

Some of the particles produced pollute the indoor air, causing health and safety risks, including human inhalation. In this regard, care should be taken against smoke poisoning. Smoke exhaust fans are the most logical solution to this problem. Smoke exhaust fan evacuation should be carried out with ERF Group product range according to strict standards that require the intervention of a qualified professional.

Smoke exhaust fans, by their very principle of operation, are used to filter and remove toxic particles and dust from the working environment. Most companies will be subject to strict health and safety rules from governing bodies to implement such systems.

Smoke exhaust fans are like an air filter that sucks dirty air into the room and then returns clean air that has passed through the filter. After filtration, all toxic and dust particles are trapped inside the filter. Smoke exhaust fans prevent the spread of fire by discharging heat, gases and unburnt materials to the outside.

Smoke and flammable gases produced by fire often disrupt and sometimes prevent the evacuation of occupants and the effective response of emergency services in buildings in case of fire. In this regard, the smoke exhaust fans installed by ERF Group are very controlled.

ERF Group smoke exhaust fans have three different stages. After hazardous substances have been captured by the filter system, they enter the first filter stage, where large particles are trapped into medium or fine dust particles using a pre-filter.

The air then passes to the second stage filter where much smaller particles are captured in an EPA or HEPA particle filter. The final third stage filter is for gases. It removes gases, odors, adhesives and solvent fumes.

The result of a 3-layer smoke exhaust system is that clean air is recirculated in the workplace free of toxins or harmful particles. Selecting a suitable fume exhaust fan system from the ERF Group product portfolio depending on the workplace and type of application

There are two types of smoke exhaust fan systems: volume extraction and pin extraction. Volume extraction is most suitable when coverage over a large area is required. Fume exhaust fans are the best solution, which are often preferred in areas such as hand soldering welders, robotic or welding baths, adhesive and chemical microscopic welding.

In general, many workplaces have numerous regulations regarding smoke extraction with the principle of natural smoke extraction. In ERF Group product installation processes, regulations regarding natural smoke evacuation also differ depending on the building. In this context, it installs the most suitable exhaust smoke fans with its expert staff and quality product range.

When choosing how to choose the right fume exhaust fan all types of solvents and chemicals always come with a material and should always be read. There is a document that lists all the health and safety information for that material. It will often list all the chemical compounds found in the material and will offer guidance on use and handling.

In some countries where we use hazardous substances in the workplace, the employer is legally required to provide the employee with information, instructions and in some cases training where employees may be exposed to the substances. To choose the right exhaust fan, you should always start with the MSDS.

After use, you will have all the information listed by ERF Group staff to indicate the type of particles in the workplace. The necessary information and recommendations are provided to customers by ERF Group.

The useful opening surface of ERF Group smoke exhaust fan grilles is installed depending on the thickness of the smoke layer, which is determined by the type of operation, the height of the room and the vertical height of the curtains. The effectiveness of natural smoke extraction also depends on the surface area and the placement of the fresh air ducts in the lower part of the building.

In this context, the most important issue to be considered in order to reduce the content of toxic gases, maintain adequate oxygen levels and maintain maximum visibility is the smoke exhaust fan. Each building is different due to its structure and size and therefore it is necessary to design a smoke evacuation installation adapted to each building type.

The installation of an ERF Group exhaust fan is carried out by means of a pulling or sweeping effect between the two facades of the building to ensure a satisfactory evacuation of the volume of smoke to be removed. The ERF Group exhaust fan installation is done as follows:

Smoke exhaust fans should be installed in such a way that fresh air is brought into the lower part of the space through smoke exhaust louvers.

For smoke and heat extraction in the upper part of the building through smoke vents in the roof or openings in the facade, the external fresh air inlets should be located in an area not affected by smoke.

Fans circulate the air in the space and provide sufficient oxygen to the working environment. Depending on the model, fans can be easily mounted on the wall or used as the end of larger pipe ventilation systems.

Smoke exhaust fans, which are installed in every area where production is carried out in workplaces, are made by ERF Group in a highly professional and appropriate manner. In this context, smoke exhaust fans both provide clean air and have many different advantages.

Smoke exhaust fans prevent internal burns caused by inhalation of hot gases. Smoke is an important factor in the spread of fire due to its temperatures that facilitate pyrolysis and ignition of combustible materials and its composition containing a large number of unburned gases. Smoke exhaust fans play a very important role in this regard.

The consumption of oxygen by fire due to a lack of oxygen in a production facility can cause workers to faint and even lead to death. In this regard, smoke exhaust fans have systems that provide the most appropriate safety and precautions.

Smoke exhaust fans guarantee the control and evacuation of smoke, gases and heat. Smoke extraction thus creates a free air height with an acceptable level of oxygen and visibility under the smoke layer, making it possible to evacuate all combustion products, significantly reducing the concentration of toxic gases and significantly reducing the temperature.

In all this process, the fan in the ERF Group products and in the workplace or in any other area has a very important place. These fans, which provide advantages in terms of use, are also long-lasting and can be used for many years.

ERF Group fans are available in a wide range of designs and drive types for every conceivable application, in every situation considered. The spectrum ranges from low-pressure to high-pressure models and for every requirement there is a fume exhaust fan with power characteristics suitable for the specified operating point.

Models for high or low process temperatures, aggressive media or solids are available and explosion-proof versions are also available. ERF Group products with low acoustic power are optimally suited if you need a standard design or a customized design for integration into your plants.