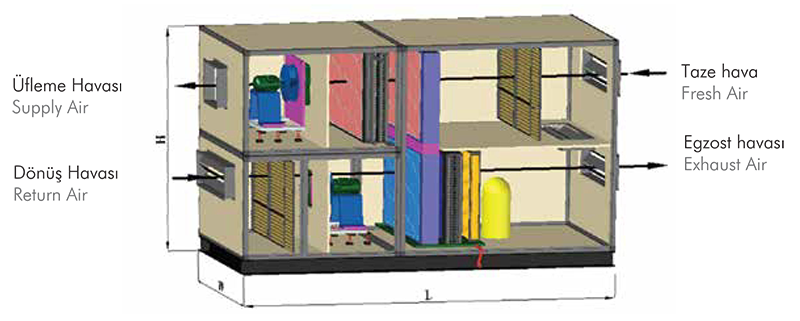

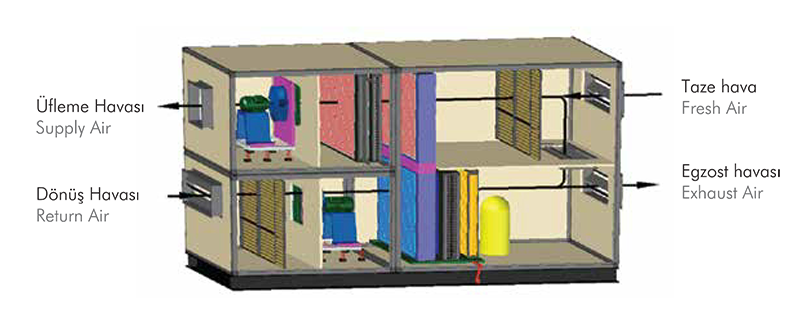

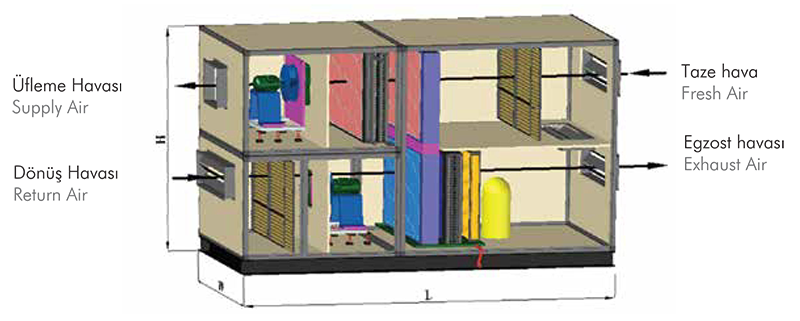

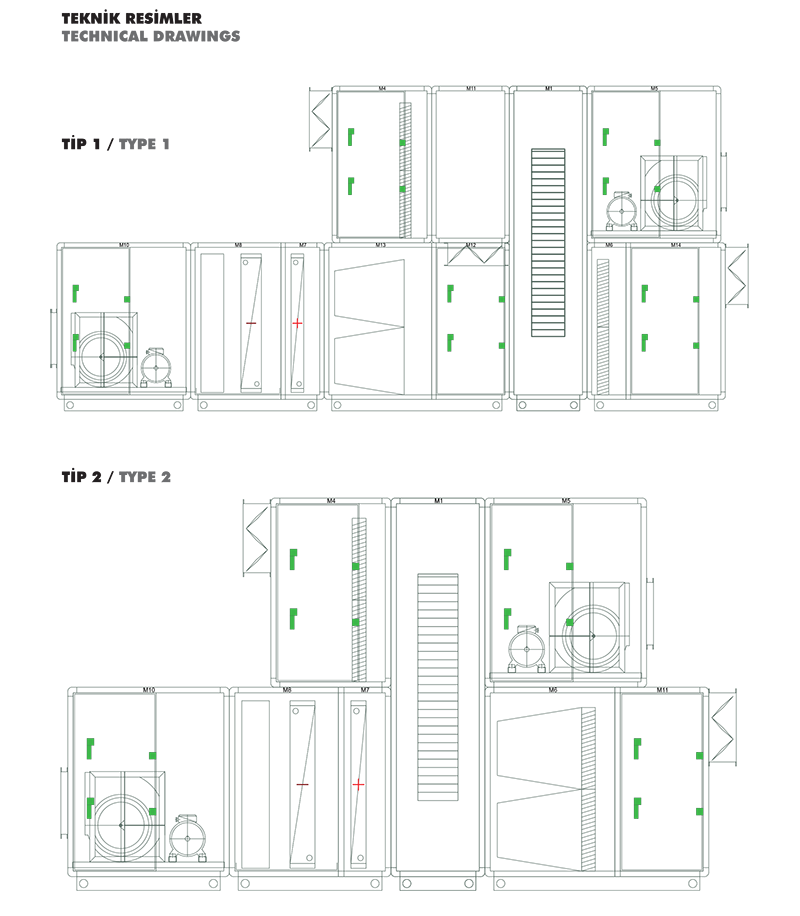

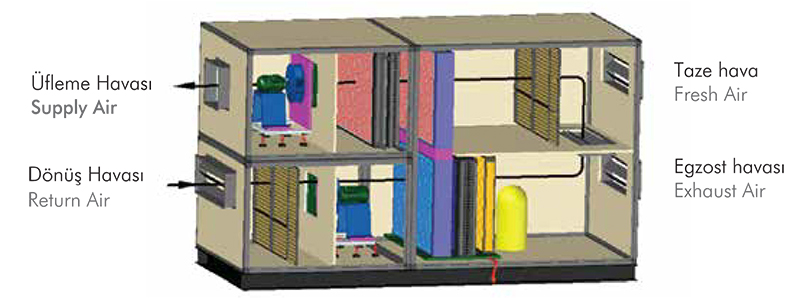

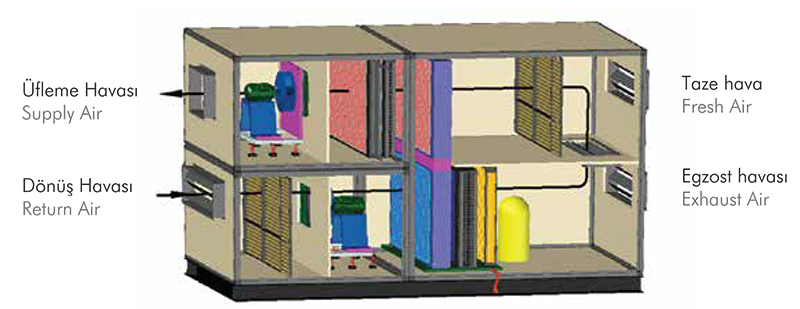

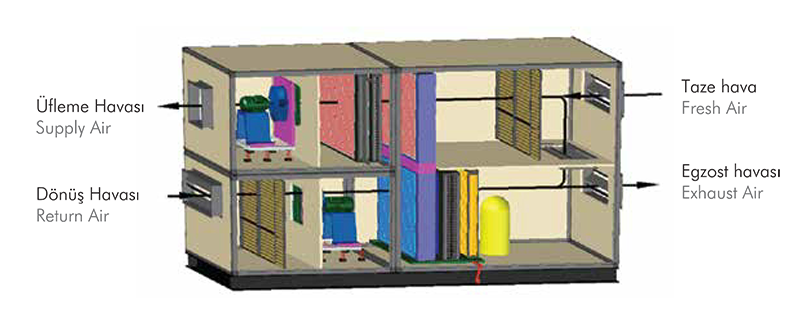

Air Handling Unit

- Production with 800 - 100,000 m3/h flow rate.

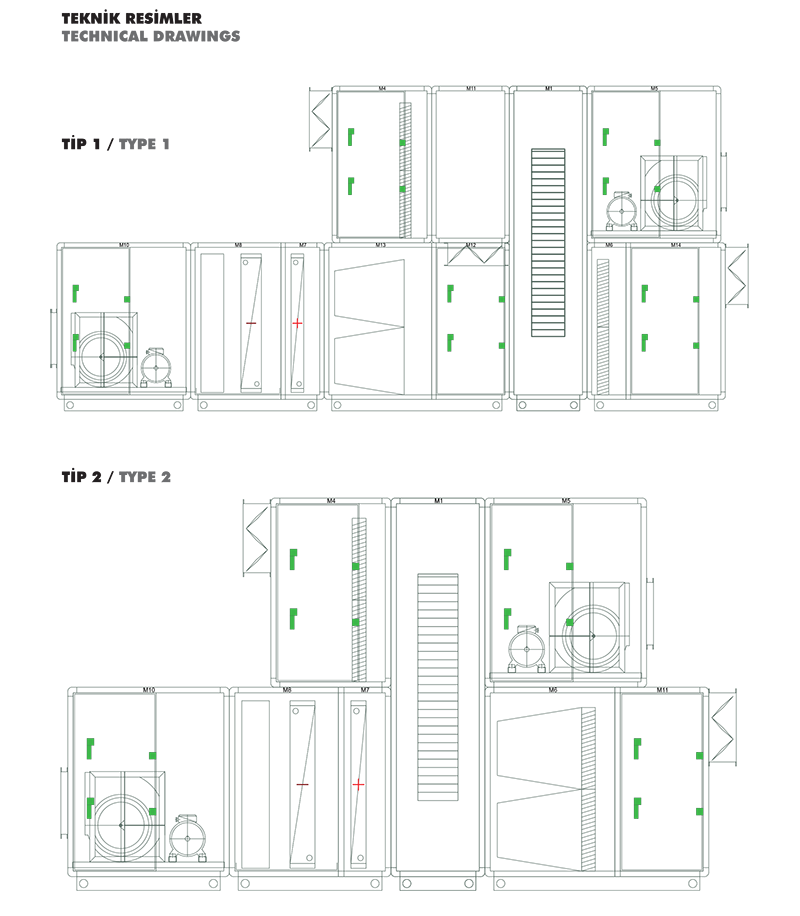

- 20 different models and a wide selection.

- Ability to be disassembled thanks to the modular system

- Easy pointing and mounting

- Tolerant values and maximum efficiency in the selection of fon, heater, cooler, filters, dompers, electric motor, heat recovery device and muffler.

HEAT EXCHANGERS

- It consists of elemonlordon with aluminum lommels on an immo and cooling coniörled copper pipe.

- The collector is made of anti-corrosive painted tubular steel.

- In the selection of heat exchangers, the hovo transition speed is a maximum of 3.4 m/s and a maximum of 2.85 m/s in the cooler heat exchangers.

- The minimum 1 row, the maximum 12 rows can be produced with 2.1 mm, 2.5 mm or 3.2 mm lomel spacing of the condenser.

- Heat exchangers are manufactured with 2522, 4035 and 3833 coliplonndo and 3/8" - 1/2" - 5/8" pipe sleeves.

- The heat exchangers are mounted inside the device to move on the slides.

- There is a sleeve on the collector to attach the hovo air vent.

- The collector bar end is threaded and has a protective PVC top.

DRIP RETAINER AND CONDENSATION PAN!

- If there is a refrigerant heat exchanger, PVC or aluminum conoth drop arrester is used regardless of the air passage rate.

- 1.5 mm thick stainless steel ton mammoth condensation pan, heat exchanger and drip trap are supplied together with the condensation tovosi resistol siphon assembled.

- The drop catcher can be taken out of the device with a slide.

- The condensation pan drainage siphon is supplied with the device in a fully-assembled state.

- Drip holder konotlon mox. design that will hold water.

Humidifier

- Steam humidifiers of "water level system" or "pulsed energy system" types are used in the plant as humidifiers.

- The diffuser blowing steam in the air is made of stainless steel and is designed to distribute the humidity homogeneously.

FILTERS

- Filters comply with ASHRAE standard.

- Filters G2 normundo mineral, G3-G4 normundo as synthetic fiber coset; F5-F7-F9 normundo bag; or H13.H14 normundo hepo filters.

- The number of filters is determined by considering the maximum flow rates that the country can give at the appropriate air passage speed specified by the manufacturer.

- G243-G4 cassette filters are mounted with slide veto easy mounting frames inside the air handling unit.

- F5-F7-F9 bag filters and H13-H14 hepa filters are mounted with easy mounting frames.

- Pressure loss values showing that the filters have become dirty are seen on the labels placed outside the cell.

- In order to facilitate the assembly of the differential pressure monometer outside the cell, holes are drilled in such a way that they hit the filter cell outer part, the filter inlet and the filter 91, and these holes are sealed with the ball.

- If desired, Hepa h13 nuclear, active carbon filter cartridge and fiber filters impregnated with activated carbon can also be used in the power plant.

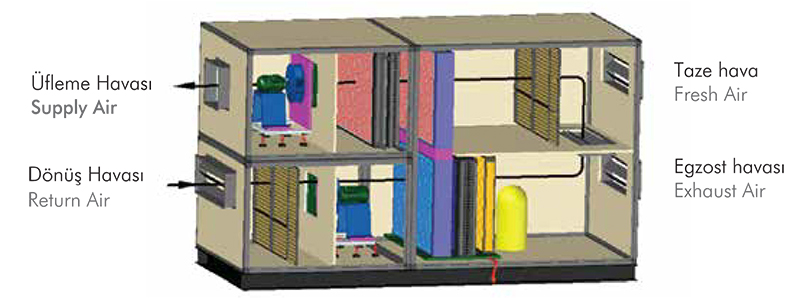

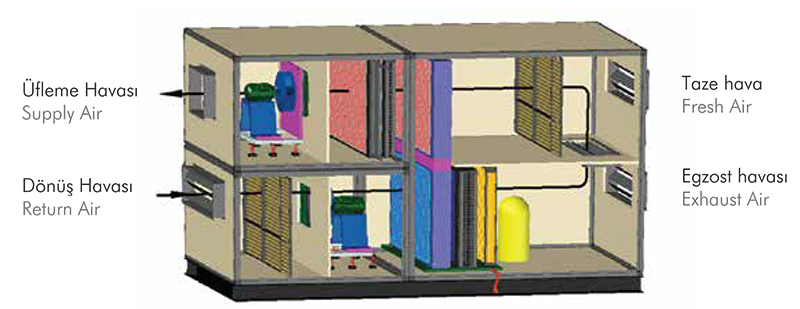

Pool Dehumidification Plant

PDP type package units are special air handling units designed to remove excess moisture from surface evaporation in indoor swimming pools and to provide optimum comfort throughout the year in the pool area.

If the relative humidity rises above 60%, it not only disrupts the comfort conditions, but also causes condensation on the walls and windows, and damages all the installation elements in the space.

PDP series air handling units are package type air conditioning units designed to provide the highest comfort conditions within the pool and to eliminate high absolute humidity when necessary.

NIGHT OPERATION WITH NO DRY PROCESS

The return air fan is turned off and the supply air is operated. The cooling circuit is closed. The return air is passed through the mixing damper and the after heater to heat the pool area with sufficient air.

NIGHT OPERATION WITH DRY PROCESS APPLIED

In night operations where usage is not intense, dehumidification is performed by passing the return air through the Heat-Pipe heat recovery battery and then through the evaporator. The dehumidified air is sent to the room in a heated state. (It is heated up to the desired values when necessary.)

DAY OPERATION WITH DRY PROCESS

The required amount of fresh air is mixed with the return air. The return air is passed through the Het-Pipe heat recovery botriosin and then through the evaporator, and the nebulisation process is carried out. After the mixture is kneaded, the dehumidified air is passed through the Heot-Pipe upper part, frost and condenser, and sent to the mohole in a heated state. Return air is exhausted as well as fresh air.

You can examine our air handling units model.

DAY OPERATION WITH NO DRY PROCESS

Low level of fresh air is used.

When necessary, only heating is done.

Compressor is off.

OPERATION IN SEASONAL TRANSITIONS (YES/NO DRY)

Dehumidification and ventilation processes are carried out with maximum outside air.